-

Metal Injection Molding

-

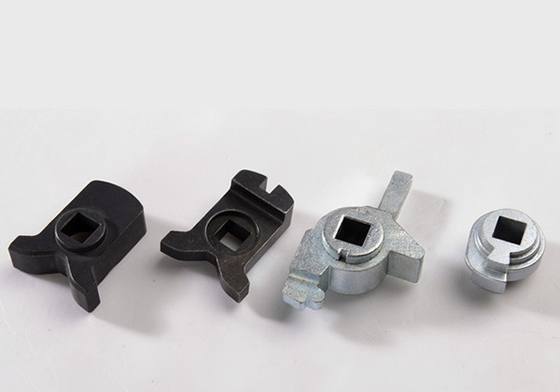

Lock Parts

-

Electric Tool Parts

-

Consumer Electronics Parts

-

Military Accessory

-

Medical Devices Parts

-

Powder Metallurgy Parts

-

Precision Auto Parts

-

Powder Metallurgy Gears

-

MIM Gear

-

Household Appliance Parts

-

Industrial Equipment Parts

-

Customized Metal Parts

-

Watches Accessories

-

Metal Injection Molding Parts

-

Michelle from EuropeanChris, these parts have passed our test in one time and thanks for your strong support, and i will send PO to you later, please check it.

ODM ISO9001 TS16949 Steel Lock Latch Bolt With Black Oxidated

| OEM OR NOT | OEM | Material | MIM4605, Fe2Ni, MIM4140 |

|---|---|---|---|

| Color | Black Or Blue | Quality | ISO9001/TS16949/IECQQC080000 |

| Process | Metal Injection Molding(MIM) | Surface Treatment | Nickel Plating/ Black Oxidation |

| Tolerance | ISO 2768-MK | Packing | According To Your Requests |

| Inspection | 100% Inspection | Application | Smart Lock And Tradition Lock |

| High Light | TS16949 Steel Lock Latch Bolt,ISO9001 Steel Lock Latch Bolt,TS16949 door lock spare parts |

||

ODM ISO9001 TS16949 Steel Lock Latch Bolt With Black Oxidated

| Brand name | OEM & ODM |

| Product type | Lock bolt and locking shifting fork |

| Product Model | NO |

| Material | steel, iron. |

| Post-Sintering | black oxidattion or zinc plating |

| Size | Customized |

| Tolerance | ISO 2768-MK |

| Weight | ≤20g |

| Forming Method | Powder Injection Molding |

| Sintering method | vacuum sintering |

| Sintering environment | Vacuum |

| Application | Lock |

| Shape | Custom |

| OEM | Accept |

| QC system | 100% inspection before shipment |

| Payment terms | T/T at sight, Paypal, Western Union,etc. |

| Lead time | 25-30 working days(included mold manufacture time) |

| Supply capability | 8000 Piece Per Day |

| Packaging | PP bag / Anti-static film / anti-static plastic disc |

What's the MIM technology and its advantages and features.

1, MIM is an advanced metal forming technology that use injection molding machine to manufacturing precision and complex metal parts, which combines the advantage of PM and plastic injection molding.

it’s suit to do mass production with complicated shapes;

it can use all kind of metal material(such as stainless steel, iron, ceramic and titanium, etc)

its relative density can achieve more than 98%

its finished products is close to final products, reducing the post-treatment cost, and then save production cost

compared with tranditional CNC and precision casting process, the structure are more even and preformance is much better

compared with PM(Powder Metallurgy), MIM can produce more complex shape and better preformance metal products.

MIM material

| Material | Composition |

| Low alloy steel | Fe-2Ni, Fe-8Ni, MIM4605, MIM4340 |

| Stainless steel | 316L, 17-4-PH, 304, 440, 420 |

| Tool steel | 42CrMo4, M2, Skd-11, C45 |

| Carbide | WC-Co(6%) |

| Ceramics | Al203, ZrO2, SiO2 |

| Tungsten alloy | W-Ni-Fe, W-Ni-Cu, W-Cu |

Compare with other process

| Parameter | MIM | CONVENTIONAL PM | MACHINING | INVESTMENT CASTING |

| Density | 98% | 88% | 100% | 98% |

| Tensile Strength | High | Low | High | High |

| Elongation | High | Low | High | High |

| Hardness | High | Low | High | High |

| Min. Wall Thickness | 0.5 mm | 1 mm | 0.5 mm | 2 mm |

| Complexity | High | Low | High | Medium |

| Surface Finish | High | Medium | High | Medium |

| Production Volumes | High | High | Low | Medium |

| Range of Materials | High | High | High | Medium-High |

| Cost | Medium | Low | High | Medium |

Service:

1, 100% inspection before shipment.

2, Satisfied packing, carton, wooden case, pallet,or according to your requirement.

3, Samples are within 35-40 days after the receipt of the deposit. production will be finished about 25-30days after samples confirma

INSPECTION EQUIPMENT

![]()

Certifications:

● ISO 9001:2009 ● ISO/TS 16949:2009 ● IECQ QC 080000

![]()

If you are interested in lock parts, please send me 2D or 3D drawings, and then we will evaluate them and offer you a nice price